Wood as raw material

As Polish business we are using our local supplies of pine wood to create safe and durable construction that will not only make your kids smile but also will nicely fit in your garden space.

In Apila we use best selected wood parts that comes only from re-forestation. This natural, durable and self-renewed material is provided to you with FSC certification that proves our playgrounds come from sustainably managed forests. We are proud to use recyclable, CO2 neutral wood as base raw material for joy and happiness of little ones. That also comes with our awareness of environmental threat we struggle with nowadays.

About Wood Features

01

Maintenance:

Please plan your first timber maintenance before first winter after assembling. You can only use the varnish that is appropriate for the products for children, to make sure you choose the correct one please consult the professional in the store where you buy the varnish. You are free to use the transparent or coloured varnish and you can choose the colour that you like but please remember that you will paint a coloured timber so the final colour may differ from what you expect. If you want to have close match to the original colour, please take a piece of timber from your playground to the shop where you buy the varnish and compare it. As to the painting process please follow the information placed on the pack.

For more information on maintenance please check warning section in the product manual.

02

Dark marks and stains:

Bluish (sometimes getting close to black) stains or marks may appear on the wood. It is caused by fungi that feed on the living cells of the sapwood. Blue stain, in principle, does not adversely affect the mechanical properties of the wood, it only reduces the aesthetics and makes it difficult to impregnate. Elements with blue stain should be additionally protected with an antifungal agent for external use or simply repainted with an impregnation agent, this should stop the development of blue stain. If the blue stain area is too large (e.g. it covers more than 20% of the surface of the element), please contact us, we will replace such elements.

03

Green bloom:

The wood may be slightly discoloured in green or white colour, in the form of streaks, stains or dots in such colours. This is normal, you don’t need to worry. This is a sign of the reaction that takes place between the organic content of wood and the impregnation used to protect the wood. The effect is the precipitating green or white salt crystals, which over time “melt” into the structure of the wood or are washed out. If you want to get rid of them right away, you can gently sand them with sandpaper with high granulation.

Attention! To ensure an exact fit small holes are not pre-drilled. In user manual we demand customer to pre-drill them before assembly to avoid cracks.

04

Wood core:

Sometimes a darker streak can be seen in the structure of the wood, this is the wood core (the heartwood, the primary part of the wood surrounded by the first grain). It can run the entire length of the wood element or only part of it – it results from the uneven structure of the wood (uneven arrangement of the wood grain) and is a completely natural feature.

05

Resin pockets, resin:

Resin is a natural component in wood. Coniferous wood is characterized by the so-called resin pouches (or pockets). They are often filled with resin and have the shape of an arc or a dark streak. They do not adversely affect the strength and durability of the beams, but there is a risk of resin leakage at the location of such pockets. If you can see the resin, stick a piece of paper to it to protect it and mark the leakage, wait a few days for the resin to dry, then peel off the paper and gently scrape the dry resin (looking like crystallized honey) without penetrating the structure of the wood itself.

Attention! To ensure an exact fit small holes are not pre-drilled. In user manual we demand customer to pre-drill them before assembly to avoid cracks.

06

Mold:

Mold are fungi that are on the surface of wood and are caused by the moisture in it. The wood for our playgrounds is dried before processing, but we cannot prevent the absorption of water from the air or from atmospheric precipitation, which in the end can cause mould. To avoid this, we recommend opening the package with wood as soon as possible and unpacking the wooden elements so that they can gradually “get rid” of excess moisture. It is best to arrange the elements so that they do not touch each other. Even the minimum space between the elements will help them dry out. However, when mold does appear, it is important to detect its presence as early as possible and react, just wipe it off with a cloth and dry the place where the mold appears. It is also good to protect this place with an anti-mold agent or an impregnation agent, following all the safety rules applicable to the use of the agent. Mold, unless advanced, does not deteriorate the quality of the wood. Attention! If the mold is not removed, it can rot over time and cause significant degradation of the wood.

07

Cracks:

Wood that is exposed to external factors reacts to changes in humidity. It can shrink when dry or expand in volume when wet. It is a natural process and cannot be prevented. Volume changes usually cause cracks to appear. It is approved that cracks up to 1/4 of the length or cross-section do not change the strength of the wood. That is why the wood that we use for the production of playgrounds is dried before processing to minimize the scale of secondary cracks.

Attention! To ensure an exact fit small holes are not pre-drilled. In user manual we demand customer to pre-drill them before assembly to avoid cracks.

08

Slight edge losses:

If you notice a loss on the edges or sides of the wooden elements, take a closer look, we recommend that you carefully check if the defect does not contain sharp edges and if you find them, please soften them with sandpaper. If the loss is significant or raises any doubts, please send a photo to us – we will contact you and together we will assess whether a given element requires replacement.

09

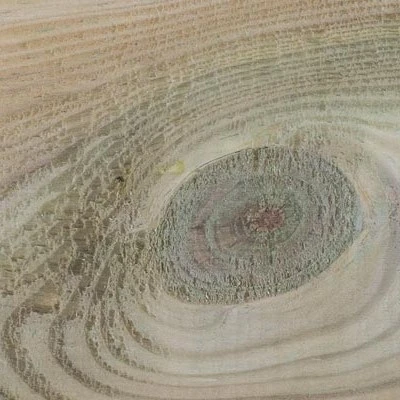

Undistorted in the vicinity of knots:

We try to carefully sand our wood, but sometimes there are places that are difficult to work with, especially around knots. The result is small rough surfaces next to the knot on the side from which the wood planning knives ran. This does not affect the durability of the playground in any way and is not subject to complaint.

10

Microcracks:

Wood is a natural material that react to changes in humidity and temperature by expanding and/or contracting. Due to that there may appear small cracks in the wood. They run either in front of or within the length of the elements. Basically, they are not a problem for both the strength value of the wood and the aesthetics, however, we ask, especially if the elements are used in the construction of the floor or the playground barriers, to send us a photo of those elements. We will look closely at the crack and assess whether it is a real problem for the product structure.

11

Partial discoloration:

Our wood is stored in piles, during drying it is placed on special spacers ensuring airflow between the pieces. After being packed in the final package, the wood is tied and arranged in layers, while those on top of the pallet are exposed to sunlight those on sides or bottom are not or not fully. Those differences in exposition to sunlight causes the may cause partial discoloration of the wooden elements. They are by no means a defect, and colours should finally even out after a few weeks after assembly.

12

Knots:

Knot – This is a natural element of wood created by the remains of dead, fallen or cut branches embedded in the wood. They are not a defect and are an integral and natural part of the wood. Sometimes there are larger knots, they are natural in the wood, because the knots are a remnant of the branches that previously grew here, if they are stuck to the wood, stable, not loose and do not give the impression of potentially falling out, do not worry about them, however, if the knot is very large and the wooden element is mounted as an element of the playgrounds floor, please report it to us – we will replace this element for you.

13

Dimension changes:

Changes in humidity and temperature causes timber to expand and/or contract. Total deviations should not exceed 25% original size but most often it’s barely observable. This is one of many wood natural characteristics and we can’t prevent it.

Attention! To ensure an exact fit small holes are not pre-drilled. In user manual we demand customer to pre-drill them before assembly to avoid cracks.